|

Vero 公司宣佈從 VISI 12版起, 正式推出 VISI-Cam 5 軸加工模組. 此 5 軸加工模組將提供完整的 4/5 軸方案應用於模具業, 航太業, 汽車工業與多軸雷射切割的五軸加工. 超過 25 種以上的不同 5 軸加工策略, 依照不同工業別的需求分別組合成不同的模組, 允許您只選擇所需的功能, 達到以最低的價格, 創造最高的投資效益. 不論您是加工葉片, 深穴模具或引擎工件, VISI-Cam 5 軸加工模組都能提供您完整的方案.

以下介紹部份的模組與加工實例與影片播放. |

||

|

5 軸加工模組 : |

||

|

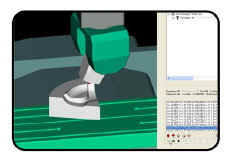

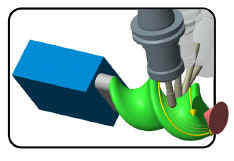

模具業 5 軸 Many complex moulds contain deep cavity areas and small radii which need to be machined with small diameter tools. Normally this would involve the use of tool extensions or longer tools which would increase the risk of deflection and provide a poor surface finish. By approaching this from a different angle, it allows for the use of shorter tools to increase rigidity and maintain a consistent and quality surface finish. This approach also benefits from shorter tool movements, reduced programming and cutting time plus fewer machine set-ups. VISI-Series creates true HSM

strategies within its 5 軸

toolpaths for mould and die and can

work on either Solid, Surface or STL models. The mould and die

application supports multiple tools shapes including Ball nose,

Tapered ballnose and ‘lollipop’ style cutters. |

|

|

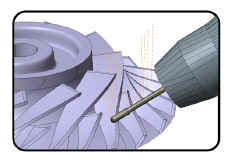

航太業

5 軸 VISI-Series provides a dedicated and powerful feature set for the machining of all Aerospace type requirements including turbine blades and aero structures. Single set-up, enhanced surface finish, increased reliability, multiple tool type support and advanced collision avoidance are just a few of the many benefits available to aerospace manufacturing companies. |

|

|

|

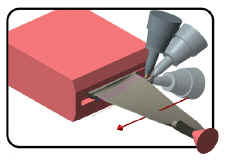

汽車業 5 軸 5 軸 machining in the Automotive industry covers many areas from plastic trim and drive train to engine components and turbo impellers. VISI-Series caters for the complete spectrum of machining requirements for automotive manufacturers. Machining of turbo impellers is probably the most recognised of 5 軸 machining requirements and this is primarily due to the advanced collision control that is required. By using the ‘swarf cutting’ options within VISI-Series optimum machining of impellers is a simplified process. Other specialist areas of manufacture include the machining of engine inlet and exhaust ports. Many

manufacturers are developing reduced emission engines and it is

imperative that these areas are optimised to provide better

performance with reduced fuel consumption. The dedicated port

machining routine included within VISI-Series ensures that these

optimum levels can be achieved. |

|

|

|

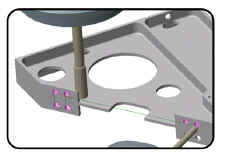

進階方案 Trimming

of vacuum formed or GRP/Carbon fibre moulded components can be

achieved with ease. Swarf cutting routines trim the desired

shape using the side of the cutter. |

|

|

Visi 5軸功能圖示 Visi 4軸功能圖示 |

||

|

|

|

|

|

|

|

|

|

|

以刀側5軸加工音箱面板 |

以上為中工木工5軸同動機器加工範例 |